hermal sublimation process

principle

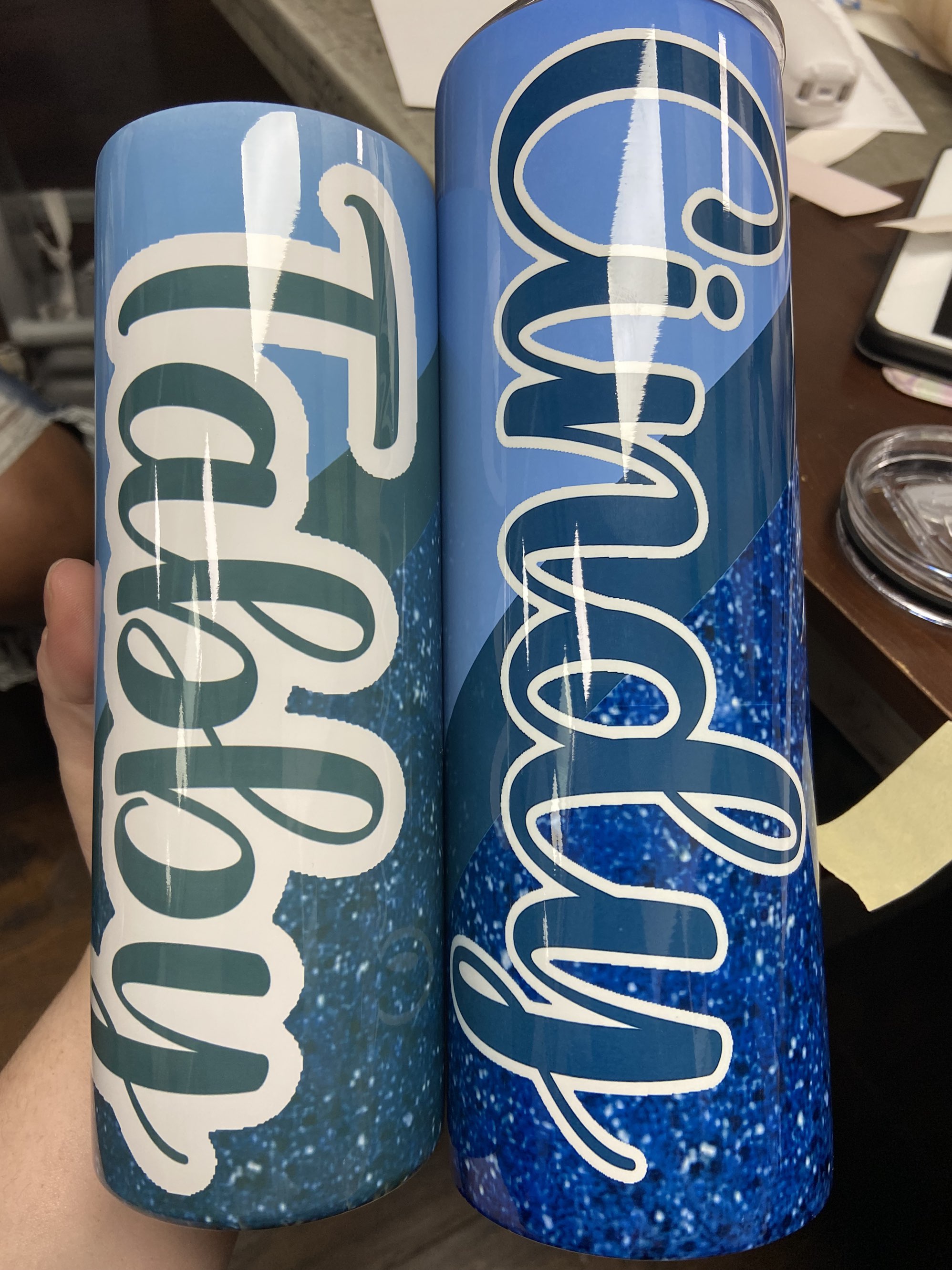

Thermal sublimation process belongs to a branch of thermal transfer printing process, which is a transfer printing process, mainly using disperse dyes. The printing principle is to print the pattern on the thermal sublimation transfer paper with special dyes, and then transfer the pattern on the transfer paper to the fabric. By using the sublimation characteristics of disperse dyes at high temperature, the dyes are diffused into the fabric at a high temperature of about 200 ℃.

characteristic

1. Good color fastness and high durability. The dye directly infects the fabric in the sublimation process, and integrates with the garment. The printing life is the same as the garment life, and the durability is good.

2. Thermal sublimation technology can express the patterns more finely, with distinct layers, bright colors and three-dimensional sense.

3. Green environmental protection, no pollution, simple equipment, no water washing, and reduce sewage discharge.

The difference between thermal transfer printing and hot stamping

Both thermal sublimation process and hot stamping belong to thermal transfer technology, and both need to be transferred by transfer paper in a high temperature environment. The difference is that the thermal sublimation technology mainly uses disperse dyes, and through the sublimation technology, the dyes enter the fabric to color the clothes. More materials can be used for hot stamping, such as PU materials and hot stamping paper, which can create various effects such as fluorescent glue Q hot stamping and hot stamping. The pattern is on the surface of the fabric and does not penetrate the interior.

4.Thermal sublimation, which means that the primary color CMY (blue, red and yellow) pigments are sublimated into gas phase by a semiconductor element heating device and printed on special photographic paper. Since each semiconductor heating element can adjust 256 temperatures, it is possible to adjust the proportion and intensity of colors. Make the printed image as delicate and smooth as spray, especially suitable for the delicate and delicate skin texture requirements such as portraits. The sharpness of images printed by thermal sublimation technology can not be replaced by laser and ink-jet printers.

Sublimation and thermal transfer printing are related to each other and have certain similarities. We all know that thermal transfer printing is a method of first printing graphics and text on special thermal transfer paper or other objects, and then using high temperature and high pressure to “stick” graphics and text on the surface of the substrate. The meaning of thermal sublimation is to sublimate the primary color CMY (blue, red and yellow) pigments into gas phase by using the semiconductor element heating device and print them on the special photographic paper. Thermal sublimation is mainly to heat the pigment molecules into the medium. Thermal sublimation printing technology is to use sublimation – no intermediate state is required from the gas state to the solid state and from the solid state to the gas state to realize the printing of photos and print them, Moreover, the sharpness of images printed by thermal sublimation technology is much better than those printed by laser printer or ink-jet printer.

Post time: Aug-12-2022